Libros antiguos y modernos

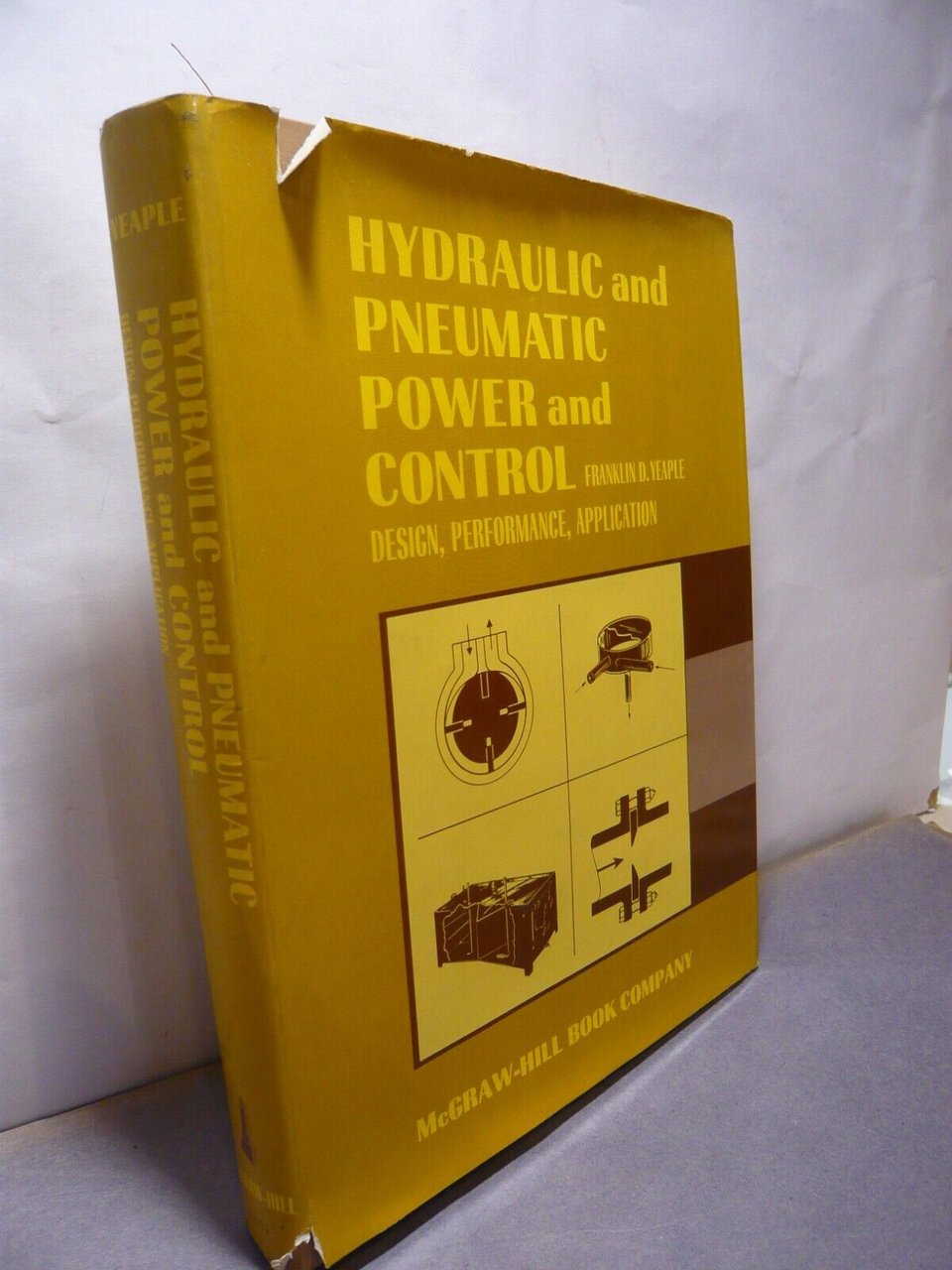

Yeaple,HYDRAULIC AND PNEUMATIC POWER AND CONTROL,McGraw-Hill,1966[idraulica

29,90 €

Modo Infoshop

(Bologna, Italia)

Los gastos de envío correctos se calculan una vez añadida la dirección de envío durante la creación del pedido. El vendedor puede elegir uno o varios métodos de envío: standard, express, economy o in store pick-up.

Condiciones de envío de la Librería:

Para los productos con un precio superior a 300 euros, es posible solicitar un plan de pago a plazos al Maremagnum. El pago puede efectuarse con Carta del Docente, Carta della cultura giovani e del merito, Administración Pública.

Los plazos de entrega se estiman en función de los plazos de envío de la librería y del transportista. En caso de retención aduanera, pueden producirse retrasos en la entrega. Los posibles gastos de aduana corren a cargo del destinatario.

Pulsa para saber másFormas de Pago

- PayPal

- Tarjeta de crédito

- Transferencia Bancaria

-

-

Descubre cómo utilizar

tu Carta del Docente -

Descubre cómo utilizar

tu Carta della cultura giovani e del merito

Detalles

Descripción

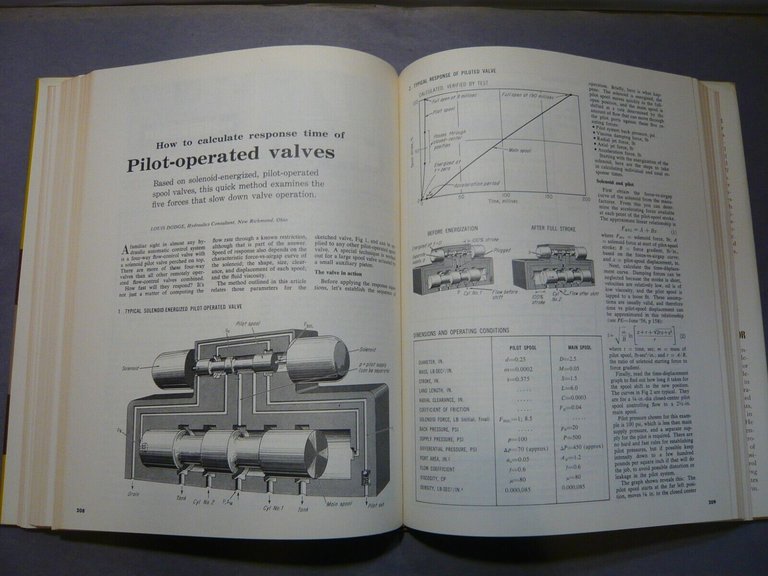

HYDRAULIC AND PNEUMATIC POWER AND CONTROL

Design, performance, application

McGraw-Hill Book Company, 1966

Copertina rigida, 29x22 cm, pp. 338

Contiene grafici, tabelle e disegni in bianco e nero

Peso: 1351 g.

Lingua inglese.

cod 7261

CONDIZIONI DEL LIBRO: la sovracopertina presenta degli strappi,

mentre l’interno è in condizioni perfette.

INDICE

Preface

Chapter 1. Fluid Properties—Oil, Synthetics, Air, and Gases 1

Modern Fluids for Power and Control: Introduction

3

What’s Hot in Fluids? For Temperatures from 400 to 850 F

8

High-pressure Air: Data to 12,000 psi

17

Chapter 2. Reservoirs and Containers—Design, Application,

Safety

21

Fluid-system Reservoir: Design and Performance

22

Oil-system Cooling: Simplified Calculations

24

Air Bubbles in Oil: A Three-pronged Attack

29

Pressurized Containers: Design, Selection, Safety

34

Chapter 3. Filters and Contaminants—Particle Size, Filter Selection

41

Measuring Fluid Contamination: Particles Smaller Than 40 microns

42

Evaluating Fluid-filtering Media: Nominal vs. Absolute Ratings

45

Chapter 4. Flexible Piping and Fittings—Hose, Couplings,

Joints, Manifolds

57

Standards for Metal Hose: Corrugated and Interlocked

58

Quick-connect Couplings Cut Costs: Representative Types, How They

Work

62

Swivel Joints: The Various Types, How They Work

66

Designing with Swivel Joints

70

Sandwich Manifolding: Eliminates Tubing and Fittings

73

Chapter 5. Flow and Pressure Drop—Equations, Measurements

75

Flow Resistance in Pipe: Summary of Equations for Fluid Friction

76

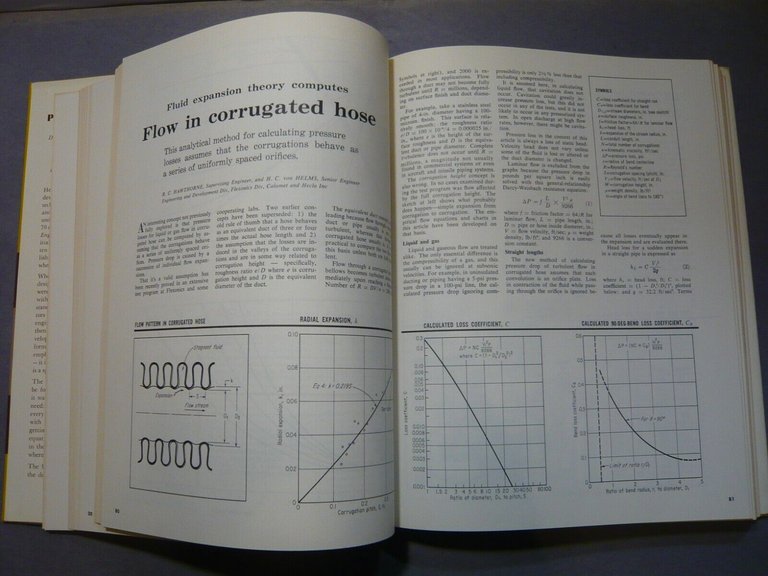

Flow in Corrugated Hose: New Fluid Expansion Theory

80

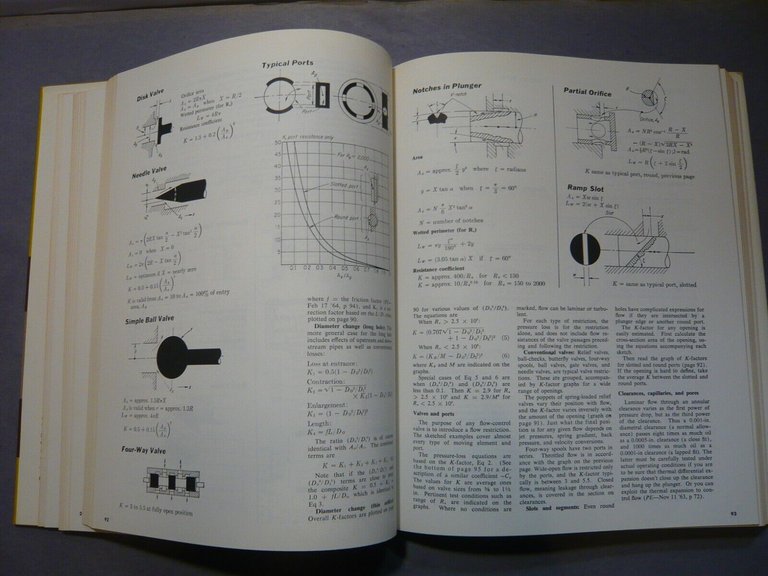

Local Resistance to Flow: Coefficients for All Fittings, Restrictions

83

Fluid Throttling Devices: For Intentional Flow Resistance

89

Close-clearance Orifices: For Flow Clearances in Thousandths

96

Errorless Orifices: Series and Parallel for Constant Discharge Coefficient

101

Airflow in Components: Graphical Solution of Flow Factor Equation

102

Which Air-flow Equation: Comparison of Ten Key Equations

112

How to Select a Flowmeter: Roundup of 16 Types

118

Chapter 6. Pumps, Compressors, and Blowers—Performance,

Application

129

Positive-displacement Pumps: Design and Performance of 17 Types

130

Cavitation in Positive-displacement Pumps: Simple Graphical Method

140

Squeegee Pump Performance: First Proven Application Technique

143

400-cycle Centrifugal Pump : Performance Compared with Regulars

151

Adiabatic Head Selects Air Compressor Type

155

Equations Find the Right Impeller: Fan Pressure and Flow Coefficients

160

Chapter 7. Valves and Controls—Construction, Performance,

Application

165

Fluid Amplifiers Go Commercial: 18 Typical Fluid Logic Devices

166

Relief Valves: Simple, Pilot-operated, Electric, and By-pass Types

169

Pressure Control Valves: Counterbalance, Sequence, Unloading, Reducing 177 Flow Control Valves:

Non-compensated, Compensated, Pilot Check

184

Directional Valves: Two-way, Three-way, Four-way, Diversion

190

Valve Circuits: Regenerative, Tandem, High-low

197

Hydraulic Servovalves: Simple Theory and Design of Basic Types

203

Pilot-operated Spool Valves: Calculation of Response Time

208

Ball Valves of Plastic: Ball, Plug, Globe, and Gate Types Compared

215

Manifold Control Valves: Five Manifolding Techniques

216

Chapter 8. Cylinders and Actuators—Stroke, Strength, Performance

223

Power Cylinder Mechanisms : Full-stroke

224

Power Cylinders: Intermediate Positions

226

Power Cylinders: Charts Give Safe Piston Rod Size

228

Six Fluid Power Force Amplifiers

230

When Pistons Need Brakes: Six Methods, Including Gearing

232

Regulate the Exhaust: Cushioning and Control of Air Cylinders

237

Chapter 9. Fluid Motors and Drives—Hydraulic, Pneumatic 239

Which Hydraulic Driver1 Hydrostatic, Hydrodynamic, Hydromechanical 241 Air Motors: Analysis and Design, Including Thermodynamics

255

Chapter 10. Dashpots, Damping, and Fluid Hammer

261

Dashpots and Damping: Practical Equations for All Problems

263

Liquid Springs: Design and Construction of Four Major Types

268

Design with Air Springs: Typical Application Has Adjustable Damping

271

Air snubbers Graphs: Shortcut Solution for Orifice Area. Pressure

272

Reduce Fluid Hammer: Theory and Design of Smoother Systems 276

Hydraulic Accumulators: Guide for Selection among Six Types 284

Chapter 11. Seals and Gaskets-Dynamic and Static Sealing 291

How to choose a dynamic Seal: Shaft, Face, Compression, Labyrinth 292

Labyrinth Shaft Seals: Leakage Equations for Non-contracting Seals 305

Bolted Gaskets: How to Select and apply the right gasket material 310

Chapter 12. System Performance—Flow Theory, Optimization, Reliability

315

Theory of Hydraulic Flow Control: Series

and Parallel Circuits

316

Split the Flow and Not the Pump: Designing Central Hydraulic Systems 332

Index

337