Rare and modern books

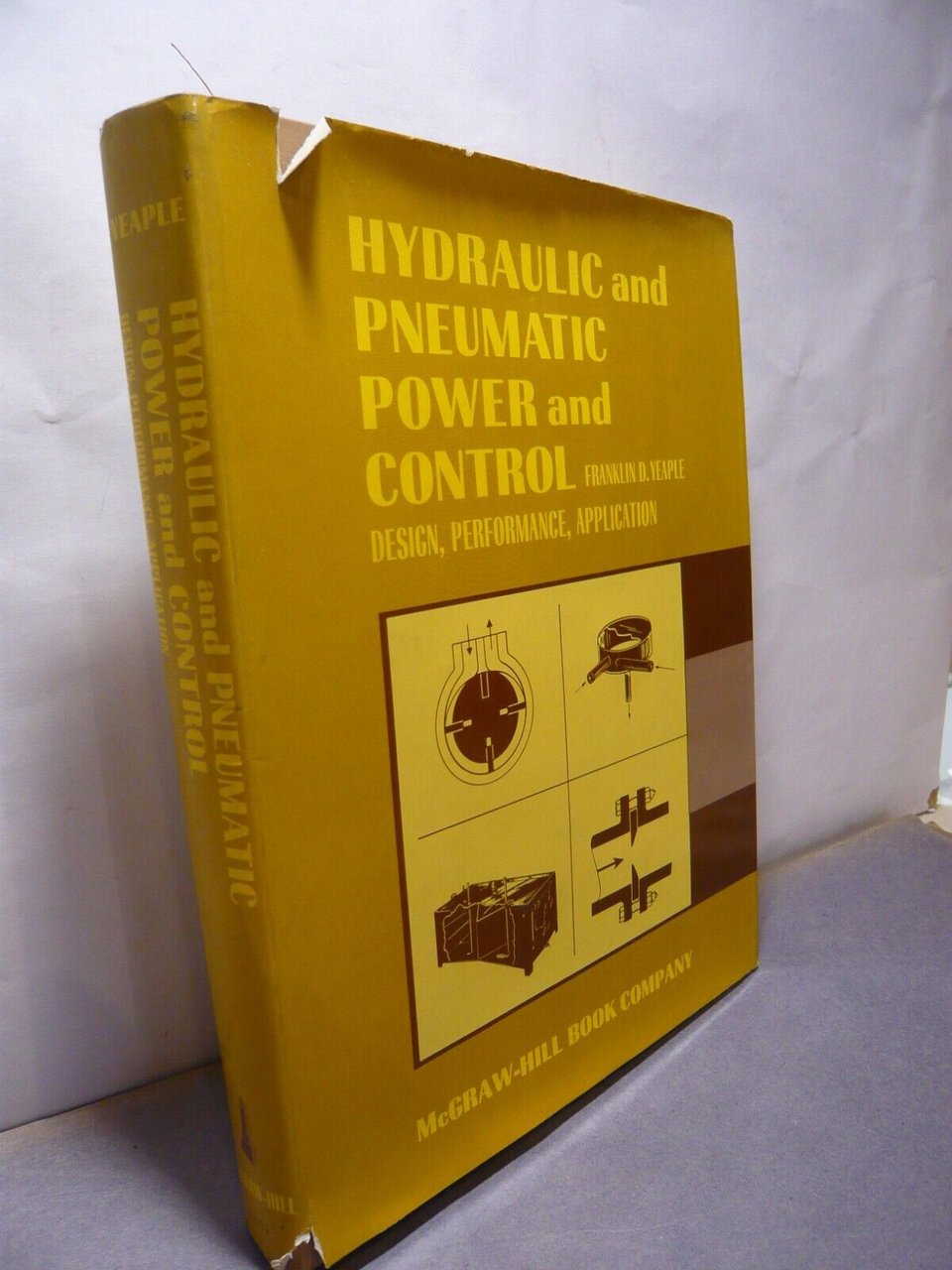

Yeaple,HYDRAULIC AND PNEUMATIC POWER AND CONTROL,McGraw-Hill,1966[idraulica

29.90 €

Modo Infoshop

(Bologna, Italy)

The correct shipping costs are calculated once the shipping address is entered during order creation. One or more delivery methods are available at the Seller's own discretion: Standard, Express, Economy, In-store pick-up.

Bookshop shipping conditions:

For items priced over €300, it is possible to request an instalment plan from Maremagnum. Payment can be made with Carta del Docente, Carta della cultura giovani e del merito, Public Administration.

Delivery time is estimated according to the shipping time of the bookshop and the courier. In case of customs detention, delivery delays may occur. Any customs duties are charged to the recipient.

For more infoPayment methods

- PayPal

- Credit card

- Bank transfer

-

-

Find out how to use

your Carta del Docente -

Find out how to use

your Carta della cultura giovani e del merito

Details

Description

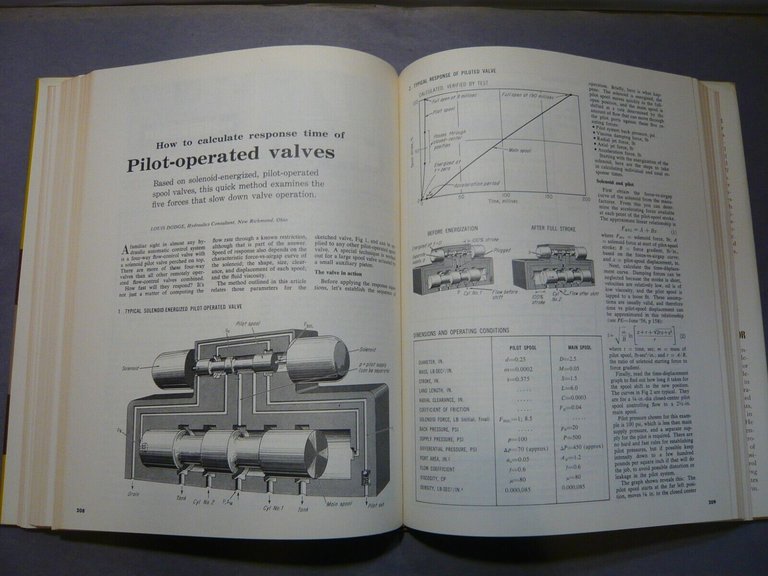

HYDRAULIC AND PNEUMATIC POWER AND CONTROL

Design, performance, application

McGraw-Hill Book Company, 1966

Copertina rigida, 29x22 cm, pp. 338

Contiene grafici, tabelle e disegni in bianco e nero

Peso: 1351 g.

Lingua inglese.

cod 7261

CONDIZIONI DEL LIBRO: la sovracopertina presenta degli strappi,

mentre l’interno è in condizioni perfette.

INDICE

Preface

Chapter 1. Fluid Properties—Oil, Synthetics, Air, and Gases 1

Modern Fluids for Power and Control: Introduction

3

What’s Hot in Fluids? For Temperatures from 400 to 850 F

8

High-pressure Air: Data to 12,000 psi

17

Chapter 2. Reservoirs and Containers—Design, Application,

Safety

21

Fluid-system Reservoir: Design and Performance

22

Oil-system Cooling: Simplified Calculations

24

Air Bubbles in Oil: A Three-pronged Attack

29

Pressurized Containers: Design, Selection, Safety

34

Chapter 3. Filters and Contaminants—Particle Size, Filter Selection

41

Measuring Fluid Contamination: Particles Smaller Than 40 microns

42

Evaluating Fluid-filtering Media: Nominal vs. Absolute Ratings

45

Chapter 4. Flexible Piping and Fittings—Hose, Couplings,

Joints, Manifolds

57

Standards for Metal Hose: Corrugated and Interlocked

58

Quick-connect Couplings Cut Costs: Representative Types, How They

Work

62

Swivel Joints: The Various Types, How They Work

66

Designing with Swivel Joints

70

Sandwich Manifolding: Eliminates Tubing and Fittings

73

Chapter 5. Flow and Pressure Drop—Equations, Measurements

75

Flow Resistance in Pipe: Summary of Equations for Fluid Friction

76

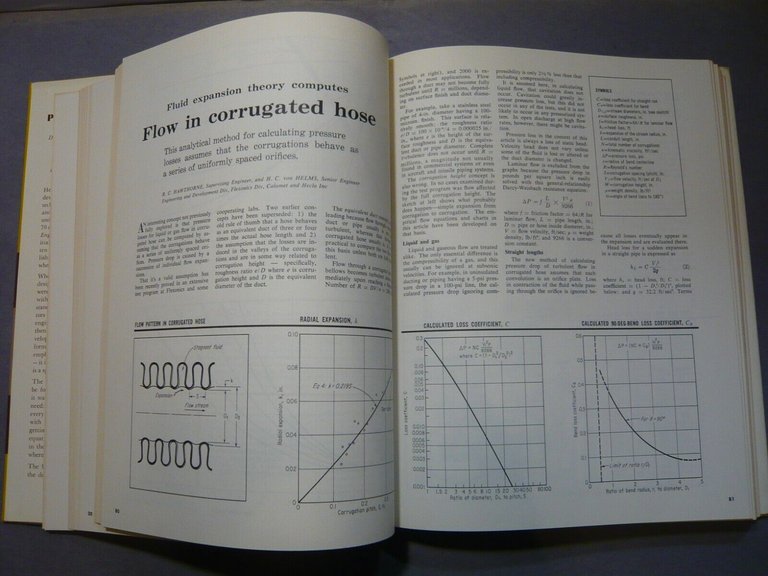

Flow in Corrugated Hose: New Fluid Expansion Theory

80

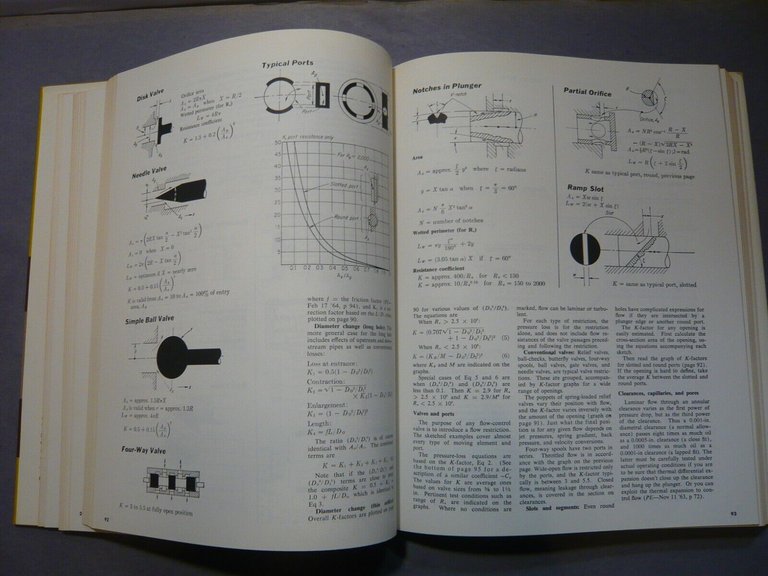

Local Resistance to Flow: Coefficients for All Fittings, Restrictions

83

Fluid Throttling Devices: For Intentional Flow Resistance

89

Close-clearance Orifices: For Flow Clearances in Thousandths

96

Errorless Orifices: Series and Parallel for Constant Discharge Coefficient

101

Airflow in Components: Graphical Solution of Flow Factor Equation

102

Which Air-flow Equation: Comparison of Ten Key Equations

112

How to Select a Flowmeter: Roundup of 16 Types

118

Chapter 6. Pumps, Compressors, and Blowers—Performance,

Application

129

Positive-displacement Pumps: Design and Performance of 17 Types

130

Cavitation in Positive-displacement Pumps: Simple Graphical Method

140

Squeegee Pump Performance: First Proven Application Technique

143

400-cycle Centrifugal Pump : Performance Compared with Regulars

151

Adiabatic Head Selects Air Compressor Type

155

Equations Find the Right Impeller: Fan Pressure and Flow Coefficients

160

Chapter 7. Valves and Controls—Construction, Performance,

Application

165

Fluid Amplifiers Go Commercial: 18 Typical Fluid Logic Devices

166

Relief Valves: Simple, Pilot-operated, Electric, and By-pass Types

169

Pressure Control Valves: Counterbalance, Sequence, Unloading, Reducing 177 Flow Control Valves:

Non-compensated, Compensated, Pilot Check

184

Directional Valves: Two-way, Three-way, Four-way, Diversion

190

Valve Circuits: Regenerative, Tandem, High-low

197

Hydraulic Servovalves: Simple Theory and Design of Basic Types

203

Pilot-operated Spool Valves: Calculation of Response Time

208

Ball Valves of Plastic: Ball, Plug, Globe, and Gate Types Compared

215

Manifold Control Valves: Five Manifolding Techniques

216

Chapter 8. Cylinders and Actuators—Stroke, Strength, Performance

223

Power Cylinder Mechanisms : Full-stroke

224

Power Cylinders: Intermediate Positions

226

Power Cylinders: Charts Give Safe Piston Rod Size

228

Six Fluid Power Force Amplifiers

230

When Pistons Need Brakes: Six Methods, Including Gearing

232

Regulate the Exhaust: Cushioning and Control of Air Cylinders

237

Chapter 9. Fluid Motors and Drives—Hydraulic, Pneumatic 239

Which Hydraulic Driver1 Hydrostatic, Hydrodynamic, Hydromechanical 241 Air Motors: Analysis and Design, Including Thermodynamics

255

Chapter 10. Dashpots, Damping, and Fluid Hammer

261

Dashpots and Damping: Practical Equations for All Problems

263

Liquid Springs: Design and Construction of Four Major Types

268

Design with Air Springs: Typical Application Has Adjustable Damping

271

Air snubbers Graphs: Shortcut Solution for Orifice Area. Pressure

272

Reduce Fluid Hammer: Theory and Design of Smoother Systems 276

Hydraulic Accumulators: Guide for Selection among Six Types 284

Chapter 11. Seals and Gaskets-Dynamic and Static Sealing 291

How to choose a dynamic Seal: Shaft, Face, Compression, Labyrinth 292

Labyrinth Shaft Seals: Leakage Equations for Non-contracting Seals 305

Bolted Gaskets: How to Select and apply the right gasket material 310

Chapter 12. System Performance—Flow Theory, Optimization, Reliability

315

Theory of Hydraulic Flow Control: Series

and Parallel Circuits

316

Split the Flow and Not the Pump: Designing Central Hydraulic Systems 332

Index

337